Below are some of the sectors where they find use:

Pipe rollers and stands are an integral part of a pipe system, providing support, safety, and proper function. The exceptional hourglass design offers pipe stabilization like no other kind. This type is made to protect and guide the tubes to pipeline projects. A particularly useful type of molded roller is the hourglass style. With the proliferation of Horizontal Directional Drilling, there is a greater demand for pipe rollers. Rollers are used in a number of industries, and anywhere that pipe needs to be conveyed to a job site. They are used to support of pipelines that expand and contract along the length of the drill, as well. Rollers are a distinct asset when it to comes to handling heavy pipe. The pipe needs to be easily accessed and quickly moved onsite. These projects exist anywhere from rural to urban areas. Electric providers use them to run conduit, and gas companies uses HDD for laying gas pipe. Towns and municipalities use them for laying sewage pipe. Companies that engage in Horizontal Directional Drilling are not limited to oilfields or offshore drill rigs. The primary advantage is the capability for transporting heavy pipe from a truck to a storage facility or a job site. What Are the Advantages of Using Roller Stands? The polyurethane rollers are designed to resist exposure to water, solvents, chemicals, and the weather. Heavy duty stands have high load bearing capabilities. The rollers use a sturdy frame that is adjustable to different heights.

OILFIELD DIRECTIONAL DRILLING MANUAL

These stands keep the tube supported as it travels smoothly toward its destination, eliminating the need for manual transport. They are used to convey a variety of materials from one point to another, and in this case, the material is the pipe used for Horizontal Directional Drilling (HDD). Roller stands sometimes referred to as roller support stands, stand with a rolling mechanism on top, typically of polyurethane manufacture. As an aid in Horizontal Directional Drilling, high-quality rollers make it a much simpler process to move the pipe from storage to transport, and then to the project. Current custom feed rollers and stands from firms such as MUI are high-tech designs, engineered and produced for specific purposes, meeting unique demands. The course covers not only regional practices but worldwide used.Today’s polyurethane roller stands play an essential part in a broad array of industrial applications.

OILFIELD DIRECTIONAL DRILLING PROFESSIONAL

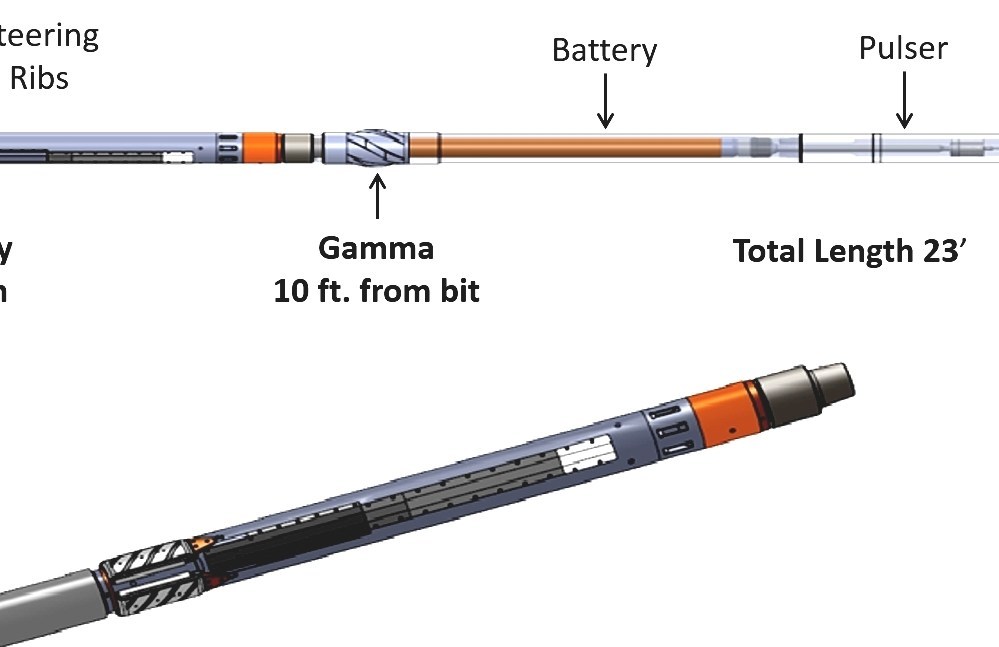

"The trainer is industry professional with a great experience to share with participants. "Very interesting and filled in gaps." - Drilling Engineer, United States Participants will be able to predict wellbore path based on historical data and determine the requirements to hit the target. Additionally, they will become familiar with the tools and techniques used in directional drilling such as survey instruments, bottomhole assemblies, motors, steerable motors, and steerable rotary systems. The basic applications and techniques for multi-lateral wells are covered in the course. Participants will receive instruction on planning and evaluating horizontal wells based on the objectives of the horizontal well. Specific problems associated with directional/horizontal drilling such as torque, drag, hole cleaning, logging, and drill string component design are included. This course builds a firm foundation in the principles and practices of directional drilling, calculations, and planning for directional and horizontal wells.

0 kommentar(er)

0 kommentar(er)